How to Fix a Stretched Metal Slinky?

Continue to rotate the Slinky to encourage additional coils to switch from the tangled side to the untangled side. In essence, you’re advancing the tangle down the Slinky until you’ve brought it to a conclusion. Twirling the Slinky around the ruler should cause it to straighten its spiral.

The kinked Slinky might be stacked on top of a baking sheet lined with tin foil and heated for about 10 minutes at 250°F (121°C) in the oven. If it hasn’t settled on its own, take it out and bend it back into position using oven mitts.

If your Slinky is stretched, you may want to know how to fix it. There are two main methods. First, you can use heat to bend the Slinky back to its original shape. This method is not very effective, but it works well enough.

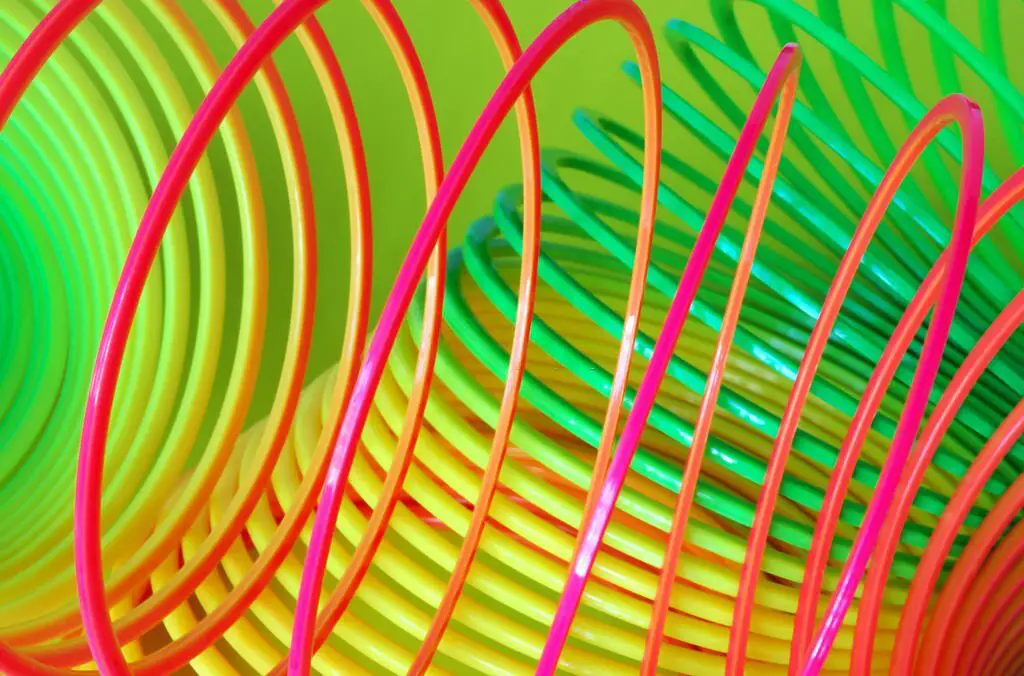

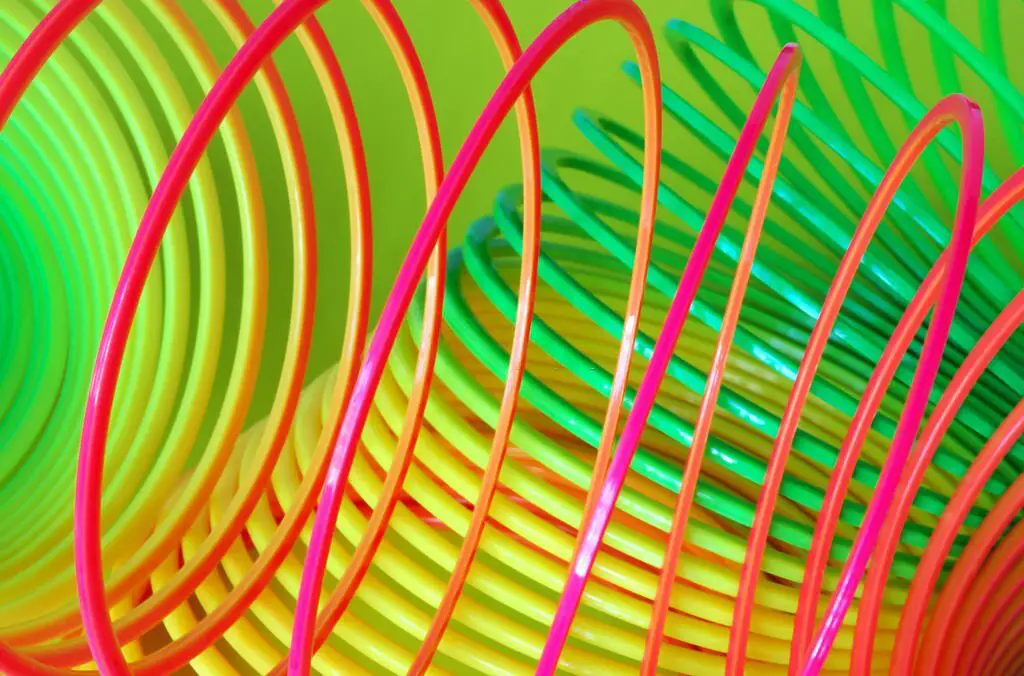

Plastic vs. Metal Slinky

Whether you have a plastic slinky or a metal one, you’ll need to find out what kind of support your Slinky needs to stretch and stay in place. In general, metal slinkies have a metal safety bracket that prevents them from tangling. This makes it challenging to use traditional untangling methods. However, one way will work if the Slinky is in a tight tangle. This is called the Spinning Method.

While plastic Slinkys cannot be repaired, metal slinkies can be heated in a pot of boiling water to soften the material. Once the metal slinky is hot, you should uncoil it and stack it on a heavy book to cool it.

The main difference between metal and plastic Slinkys is the linear mass density of each. This will affect the wave speed, so you must ensure that each Slinky has the same tension. You can also test by taping the metal slinky together and shaking the metal end.

You can also try putting two pieces of stretched rubber bands together to fix a metal slinky. One will hold the metal slinky while the other will hold the plastic one. This will fix the Slinky and make it work again.

Generally, metal Slinkys are more challenging to repair than plastic ones. But if you can’t bend it back, you can try soaking it in warm water. You can also use a book to touch it. This may help you make the metal slinky more flexible.

A plastic slinky will be more flexible and elastic than a metal one. However, the plastic material will not be as strong as metal, and if you stretch it too far, it will eventually break. So, this isn’t a good solution if you want to keep playing with your Slinky for a long time.

You can twist the metal end with your right hand to fix a stretched metal slinky. While twisting, try to keep the fingertips sticking out. Then, you can repeat the process with the other end of the Slinky.

It would help if you also tried to hold the metal end of the Slinky at the same time. This will ensure that the two ends are matched. In this way, you can easily make the slinky metal stretch again. The lower frequency of the metal slinky will be nearer to the fundamental frequency.

Mechanism of a Slinky

When held at both ends, a stretched metal slinky produces a disturbance. The disturbance propagates through the medium, where each coil interacts with the next, creating a recurrent pattern of motion and displacement. This pattern is known as a wave. For example, the first coil vibrates back and forth and displaces the second coil from its equilibrium position.

Scientists have been fascinated by the Slinky for over 25 years. Finally, they were able to quantify the phenomenon, and they were able to reproduce the phenomenon in their experiments. The mechanism is based on the principle of the force-displacement response. This theory posits that the force pulling up cancels the effect of gravity pulling downward.

The governing equations for Slinky’s motion are straightforward. Essentially, the Slinky’s elasticity is because it’s stretched more at the top than at the bottom. The bottom end is slightly stretched enough to keep it from falling for the last few turns. In the meantime, the top end of the Slinky is propelled downward by gravity and the downward pull of the spring and is then accelerated by more than twice the speed of gravity. It remains suspended at this velocity until the spring stops stretching.

The mechanism of a stretched metal slinky can be complicated, but it can be interpreted simply. It’s simple: when two hands stretch the Slinky, they exert pressure in opposite directions. As a result, a wave spanning the Slinky will form between them. The first wave is in the middle of the Slinky; the second wave has two antinodes near the hand-held ends.

The next step in untangling a stretched metal slinky is to hold one end steady and rotate it clockwise. Rotate in one direction, and the tangled loops will move further apart. Rotate the other way, and the loops will get closer together.

In the past, soldiers have used the Slinky as a portable antenna. They would fasten one end to themselves, then toss the other over a tree branch to pick up a signal. However, it wasn’t strong enough to handle the strain.

Another mechanism of a stretched metal slinky is its ability to walk down an inclined plane. When the Slinky moves down a steep plane, it will travel much faster than it would at a shallow one. So, it may take half the time, but it won’t make as many flips.

A stretched metal slinky can be repaired by using an iron. First, ensure that you use the “Wool” setting of the iron to prevent damage to the Slinky. Then, use pliers to grasp the spiral part. While holding it firmly, stretch the coils to see if the bent end has twisted.

The Slinky’s mechanism was invented by a mechanical engineer named Richard James. It was initially designed to secure cargo and equipment on ships at sea. James and his wife, Betty, had trouble selling the toy, but soon after, the first four hundred units were sold. Their company, James Industries, Inc., was acquired by Poof Products in 1998 and continued to produce the Slinky in Hollidaysburg.

Repairing a Slinky

If you’ve lost a metal slinky because it’s stretched out of shape, you can take a few steps to make it function like new again. The first step is to put it in hot water. Then, place something heavy on top of it. Then, wait for about 10 minutes. Once you’ve waited a few minutes, try to stretch the coils out by holding them firmly.

One of the easiest ways to repair a stretched metal slinky is to heat the stretched area with a hot iron. To do this, you need to use the “wool” setting. Another option is to use a tin foil pan to heat the Slinky in the oven. After you’ve done this, take it out of the water and carefully press the plastic back into place. Once it’s cool, test it to make sure it’s back to normal. If it still doesn’t work, you can try again with slightly higher heat or a longer time.

If the loops are too tangled, gently pull them apart by holding one end steady. This will make them snap back into the proper place once you release them. Alternatively, pliers can also apply pressure to a bent coil. If this doesn’t work, you can try using an iron on a towel.

A slinky can become stretched, twisted, and tangled over time. This can be frustrating and make you want to throw it away. But if you’re the type who likes tinkering, you might try untangling it yourself. There are many different methods for doing this, and it’s worth a shot.

To start this repair, you need to determine the length of the stretched metal slinky. Generally, a slinky will have two or three coils. Therefore, it probably has more than three hook points if it’s more than three. To locate these points:

- Grip one end with your right hand.

- Follow it downwards until you reach the first hook point.

- Once you’ve done this, lock all the coils between the right hand and the first hook point.

Another way to repair a stretched metal slinky is by using household materials. You can find plastic and metal household products that work well for this repair. These materials are often inexpensive, but they can make a huge difference. Just remember that using a heat source on the plastic can also cause the plastic to bend and break.

A Slinky’s energy transfer is done through an extensional wave that propagates back and forth along the axis of the spring. The speed of this wave depends on the stiffness-to-density ratio of the material. Therefore, the square root of this ratio determines its speed.

How to Fix a Stretched Metal Slinky?

Continue to rotate the Slinky to encourage additional coils to switch from the tangled side to the untangled side. In essence, you’re advancing the tangle down the Slinky until you’ve brought it to a conclusion. Twirling the Slinky around the ruler should cause it to straighten its spiral.

The kinked Slinky might be stacked on top of a baking sheet lined with tin foil and heated for about 10 minutes at 250°F (121°C) in the oven. If it hasn’t settled on its own, take it out and bend it back into position using oven mitts.

If your Slinky is stretched, you may want to know how to fix it. There are two main methods. First, you can use heat to bend the Slinky back to its original shape. This method is not very effective, but it works well enough.

Plastic vs. Metal Slinky

Whether you have a plastic slinky or a metal one, you’ll need to find out what kind of support your Slinky needs to stretch and stay in place. In general, metal slinkies have a metal safety bracket that prevents them from tangling. This makes it challenging to use traditional untangling methods. However, one way will work if the Slinky is in a tight tangle. This is called the Spinning Method.

While plastic Slinkys cannot be repaired, metal slinkies can be heated in a pot of boiling water to soften the material. Once the metal slinky is hot, you should uncoil it and stack it on a heavy book to cool it.

The main difference between metal and plastic Slinkys is the linear mass density of each. This will affect the wave speed, so you must ensure that each Slinky has the same tension. You can also test by taping the metal slinky together and shaking the metal end.

You can also try putting two pieces of stretched rubber bands together to fix a metal slinky. One will hold the metal slinky while the other will hold the plastic one. This will fix the Slinky and make it work again.

Generally, metal Slinkys are more challenging to repair than plastic ones. But if you can’t bend it back, you can try soaking it in warm water. You can also use a book to touch it. This may help you make the metal slinky more flexible.

A plastic slinky will be more flexible and elastic than a metal one. However, the plastic material will not be as strong as metal, and if you stretch it too far, it will eventually break. So, this isn’t a good solution if you want to keep playing with your Slinky for a long time.

You can twist the metal end with your right hand to fix a stretched metal slinky. While twisting, try to keep the fingertips sticking out. Then, you can repeat the process with the other end of the Slinky.

It would help if you also tried to hold the metal end of the Slinky at the same time. This will ensure that the two ends are matched. In this way, you can easily make the slinky metal stretch again. The lower frequency of the metal slinky will be nearer to the fundamental frequency.

Mechanism of a Slinky

When held at both ends, a stretched metal slinky produces a disturbance. The disturbance propagates through the medium, where each coil interacts with the next, creating a recurrent pattern of motion and displacement. This pattern is known as a wave. For example, the first coil vibrates back and forth and displaces the second coil from its equilibrium position.

Scientists have been fascinated by the Slinky for over 25 years. Finally, they were able to quantify the phenomenon, and they were able to reproduce the phenomenon in their experiments. The mechanism is based on the principle of the force-displacement response. This theory posits that the force pulling up cancels the effect of gravity pulling downward.

The governing equations for Slinky’s motion are straightforward. Essentially, the Slinky’s elasticity is because it’s stretched more at the top than at the bottom. The bottom end is slightly stretched enough to keep it from falling for the last few turns. In the meantime, the top end of the Slinky is propelled downward by gravity and the downward pull of the spring and is then accelerated by more than twice the speed of gravity. It remains suspended at this velocity until the spring stops stretching.

The mechanism of a stretched metal slinky can be complicated, but it can be interpreted simply. It’s simple: when two hands stretch the Slinky, they exert pressure in opposite directions. As a result, a wave spanning the Slinky will form between them. The first wave is in the middle of the Slinky; the second wave has two antinodes near the hand-held ends.

The next step in untangling a stretched metal slinky is to hold one end steady and rotate it clockwise. Rotate in one direction, and the tangled loops will move further apart. Rotate the other way, and the loops will get closer together.

In the past, soldiers have used the Slinky as a portable antenna. They would fasten one end to themselves, then toss the other over a tree branch to pick up a signal. However, it wasn’t strong enough to handle the strain.

Another mechanism of a stretched metal slinky is its ability to walk down an inclined plane. When the Slinky moves down a steep plane, it will travel much faster than it would at a shallow one. So, it may take half the time, but it won’t make as many flips.

A stretched metal slinky can be repaired by using an iron. First, ensure that you use the “Wool” setting of the iron to prevent damage to the Slinky. Then, use pliers to grasp the spiral part. While holding it firmly, stretch the coils to see if the bent end has twisted.

The Slinky’s mechanism was invented by a mechanical engineer named Richard James. It was initially designed to secure cargo and equipment on ships at sea. James and his wife, Betty, had trouble selling the toy, but soon after, the first four hundred units were sold. Their company, James Industries, Inc., was acquired by Poof Products in 1998 and continued to produce the Slinky in Hollidaysburg.

Repairing a Slinky

If you’ve lost a metal slinky because it’s stretched out of shape, you can take a few steps to make it function like new again. The first step is to put it in hot water. Then, place something heavy on top of it. Then, wait for about 10 minutes. Once you’ve waited a few minutes, try to stretch the coils out by holding them firmly.

One of the easiest ways to repair a stretched metal slinky is to heat the stretched area with a hot iron. To do this, you need to use the “wool” setting. Another option is to use a tin foil pan to heat the Slinky in the oven. After you’ve done this, take it out of the water and carefully press the plastic back into place. Once it’s cool, test it to make sure it’s back to normal. If it still doesn’t work, you can try again with slightly higher heat or a longer time.

If the loops are too tangled, gently pull them apart by holding one end steady. This will make them snap back into the proper place once you release them. Alternatively, pliers can also apply pressure to a bent coil. If this doesn’t work, you can try using an iron on a towel.

A slinky can become stretched, twisted, and tangled over time. This can be frustrating and make you want to throw it away. But if you’re the type who likes tinkering, you might try untangling it yourself. There are many different methods for doing this, and it’s worth a shot.

To start this repair, you need to determine the length of the stretched metal slinky. Generally, a slinky will have two or three coils. Therefore, it probably has more than three hook points if it’s more than three. To locate these points:

- Grip one end with your right hand.

- Follow it downwards until you reach the first hook point.

- Once you’ve done this, lock all the coils between the right hand and the first hook point.

Another way to repair a stretched metal slinky is by using household materials. You can find plastic and metal household products that work well for this repair. These materials are often inexpensive, but they can make a huge difference. Just remember that using a heat source on the plastic can also cause the plastic to bend and break.

A Slinky’s energy transfer is done through an extensional wave that propagates back and forth along the axis of the spring. The speed of this wave depends on the stiffness-to-density ratio of the material. Therefore, the square root of this ratio determines its speed.